CLOSE

Search for “” keywords, total search results

CLOSE

Search for “” keywords, total search results

Due to environmental concerns worldwide, the need for environmental protection and the elimination of hazardous substances in electronic components and systems have received increased attention in the semiconductor and electronics industries.

Macroblock is committed to protecting the environment and follows closely to the regulation requirements.

Macroblock has taken the steps to ensure our products complied with RoHS Directive (2002/95/EC) and customer’s requirements as well as to make sure they are Bromine (Br)-free and Fluorine (F)-free.

Chlorine (Cl)

、Bromine (Br)

CI<900ppm

Br<900ppm

CI+Br<1500ppm

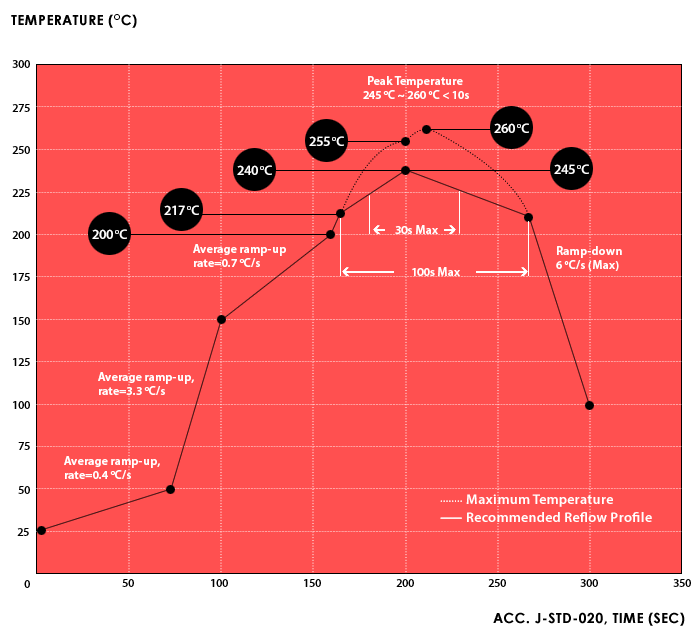

Our Pb-free semiconductor products have met the current RoHS requirements and are made using 100% pure tin (Sn) to provide both forward and backward compatibility with the current industry standards for SnPb-based soldering processes and high temperature Pb-free processes. Pure tin is widely accepted by customers and suppliers of electronic devices in Europe, Asia, and the US because the lead-free finish is preferred over tin-lead finish. Refer to JEDEC J-STD-020C for the temperature of solder bath.